Thermal Spray Coatings

High Velocity Oxy Fuel (HVOF)

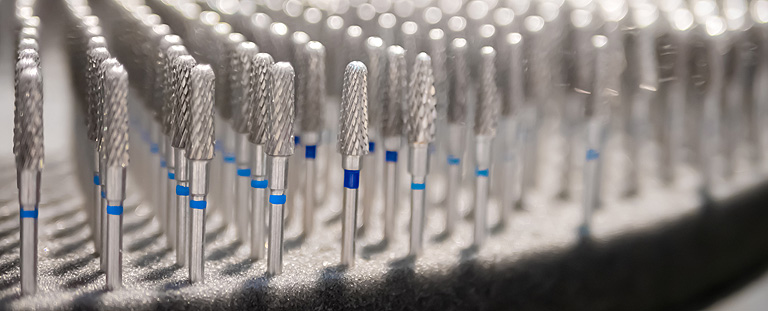

Tungsten Carbide is sprayed onto the component surface by means of a high temperature supersonic gas stream, producing a dense coating which can be ground and polished to a very high surface finish. The gas stream is produced by mixing and igniting oxygen and fuel (gas or liquid) in a combustion chamber and allowing the high pressure gas duly created to accelerate through a nozzle. Tungsten Carbide powder is introduced into this stream where it is heated and accelerated towards a component’s surface. Differing grades of Tungsten Carbide (different chemistry and particle size) give different surface properties and finishes. The coating application needs to be carried out remotely in a sound deadened booth so the shape of the component needs to be considered. Likewise masking can be challenging as conventional masking tapes, even specifically designed thermal spray tapes, are blown away by the supersonic velocity of the gas stream. We don’t currently use the HVOF system in the UK.

Plasma Coating

Here an inert gas such as Argon, when excited by an electric arc, becomes partially ionised and generates a hot gas stream having temperatures around 16,000°C. Ceramic powder is injected into the flame and projected on to a suitably prepared component to form a dense coating. It is possible to apply Tungsten Carbide using this process. The plasma gun is manipulated using a robot so the component configuration needs to be borne in mind. The chemistry of the ceramic can be varied, to achieve differing levels of corrosion resistance for example. A common application is for electrical insulation. Please note that Impreglon uses the term Plasma Coating as a generic family name for a wide range of thermally sprayed coatings and techniques. We don’t currently use the true high temperature plasma system in the UK.

For more information please complete our online form and we will get back to you as soon as possible.

With a typical 5 to 7 working day turnaround and the option of weekend and Bank Holiday working, our commitment to serving you is unrivaled. So if you have a coating need please call or email us – we’ll always give you the best coating solution advice. Accredited to ISO 9001:2008, ISO 14001:2004 and a part of the world renowned Aalberts Group.

contact us

aalberts surface technologies limited

Clover Street • Kirkby-in-Ashfield • NG17 7LJ • United Kingdom

t: +44 (0) 1623 753 107

aalberts surface technologies OCT limited

Unit 8 • Lichfield Road Industrial Estate • Tamworth • Staffordshire • B79 7XD • United Kingdom

t :+44 (0) 1827 634 89